Debarking a mixture of dry and green logs without optimizing for individual log conditions can result in fibre and value loss, even before the log is sawn. Studies have shown that, especially in winter, lumber volume loss from debarking dry logs can be more than 10%. This is because the aggressive debarking needed for frozen green logs can damage dry logs.

To reduce losses, dry logs should be detected individually to adjust debarking. After investigating several technologies, FPInnovations has developed an industrial prototype which is both robust and low-cost. A mill-hardy version has been operating semi-autonomously in a sawmill and was put through all conditions and nearly 80꙳C temperature range in nearly two years of de-risking. The sensors and hardware were shown to be reliable, working without failure or causing disruptions to mill staff. Most significantly, the mill quality control personnel were satisfied that the system performed as well as they had hoped, and the mill opted to keep the system.

Further software work is needed to enable autonomous operations, but most risk factors have been eliminated. This system is only an initial component of a future performance monitoring/optimization system. However, the dry log detection component alone could save a 100 MMBF/year debarker with 30% dry logs about $100 000 per winter month. This includes an estimated $79 000 per winter month for lumber recovery at $500 CAD/MBF lumber prices and $16 000 – $25 000 chip recovery based on the assumption that most of the log outer fibre goes to chips with 20% of lumber value. Combined with AI-based log tracking, optimizing for dry logs can also be extended to sawing and target size selection.

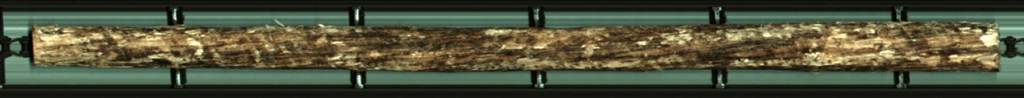

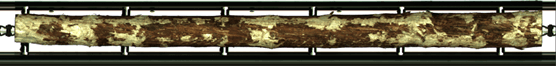

Well-debarked dry logs

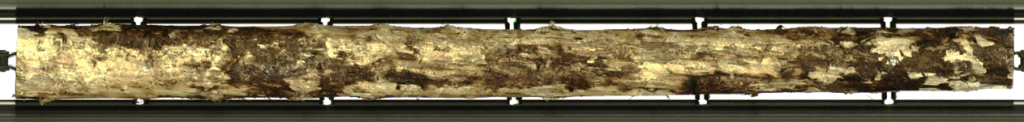

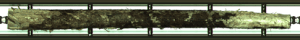

Poorly debarked dry logs